Recently, the firearm industry has been ablaze with the introduction of new cartridges. Cartridges like the 224 Valkyrie promised the AR-15 owner longer-range shots, while the 350 Legend offered hard-hitting performance at an affordable price. While new products are the gunwriter’s bread and butter, nothing warms my heart like a good Cinderella story, and this year it seems to be starring the 5.7x28 mm, originally developed by FN Herstal. Numerous firearms in this chambering were introduced in early 2020, and the cartridge even played a major part in the recent box office hit “Bad Boys For Life.”

Unlike the careers of Will Smith and Martin Lawrence, however, the 1990s were not as kind to this tiny powerhouse cartridge. For starters, it was just too darn expensive for most folks to run. Not only was the ammunition pricey, but the typical firearm chambered in it had an MSRP that was nothing to sneeze at, either. Nonetheless, those with deep pockets (like government entities) embraced it for its enhanced capabilities and its ability to provide increased magazine capacity without added bulk. These aspects kept it popular enough among professionals for the past 30 years, allowing FN to keep churning out its Five-seveN pistols and P90 PDWs to all departments and militaries that were interested.

The round itself has a lot of draw to the civilian, too. Its compact size and high velocity make it a great fit for the varmint hunter who wants to carry a bunch of rounds afield to dispatch vermin for a long weekend. Its flat trajectory make it great for unknown-distance targets. The casual pistol shooter will enjoy increased accuracy and mild recoil. Yes, places to put the round were abundant, but the means of getting it there were rather limited. However, that situation has now all but ended.

Ruger stepped up to the plate with the introduction of its 57 pistol that brought traditional controls and contemporary features to the arena at a more affordable price. CMMG also introduced several conversions that attach directly to any AR-15 lower and offer an affordable solution for the rifle enthusiast. I was fortunate enough to have one of each on hand, but of course, barely any ammunition.

During the introduction of our reloading course at Renaissance Firearms Instruction, I typically mention that chief among reasons to reload are economy and accuracy. I also like to get across that sometimes reloading needs to be done just out of sheer necessity. Well, it appears that I’ve said it so much, it came true on a personal basis—and it was going to be the only way that I would be testing these guns anytime soon. No worries, I mean how hard could it be? It’s just your typical bottleneck cartridge, right? Unbeknownst to me, I was about to open a proverbial can of worms. But hey, anything for science.

My journey began with the acquisition of brass. With factory-fresh offerings being virtually nonexistent, I had to scrounge for it. I quickly remembered a conversation with the president of my local club regarding an individual who was shooting the plate rack with this cartridge. Our concern was for both the plate rack and the shooter’s safety, as the high velocity may lead to ricochet issues at that close of a distance. Now, mind that this conversation took place more than six months before the decision to go look for that brass. Lo and behold, the brass was still there, tarnished and coated with sand. After scooping up close to 100 pieces, I used a Lyman sonic cleaner and tumbler to bring it back to a factory shine. After this, I carefully inspected each piece to ensure that it wasn’t cracked or damaged in any other way. Any time you are reloading range brass, extra safety precautions need to be taken. It turns out that the 5.7 is built with a polymer coating; while the sonic cleaner left it unscathed, the tumbler removed a good portion of it. Research would inform me that this coating is applied to aid in reliability—more on that later.

To help save the day, I gave it another 2-hour roll in some fresh media and then hit it one more time with the sonic cleaner to get off the newly embedded dirt, and cut my losses there. Time would tell if its removal meant that the cases are now useless. Conventional reloading information says that they aren’t; just don’t expect fluid-like functionality. I figured I could at least use them to determine my best powder charge and maybe even get them to cycle with a little bit of lubrication if need be. Of course, the now-uneven polymer coating is not going to do me any favors in the accuracy department. Since these aren’t benchrest rifles, let’s see if anyone even notices it.

With brass in hand, it was time to crack the books and see what was needed to make these pop again. Reloading data on this subject was pretty scarce, but I was able to find a few charts in the 49th edition of the Lyman manual. After scanning component options, I selected Vihtavuori N340 powder and 40-grain Hornady V-Max bullets. Vihtavuori powders have a reputation for excellence, and the short grain of N340 was sure to make life easier, as the entire charge range is just a minuscule half a grain.

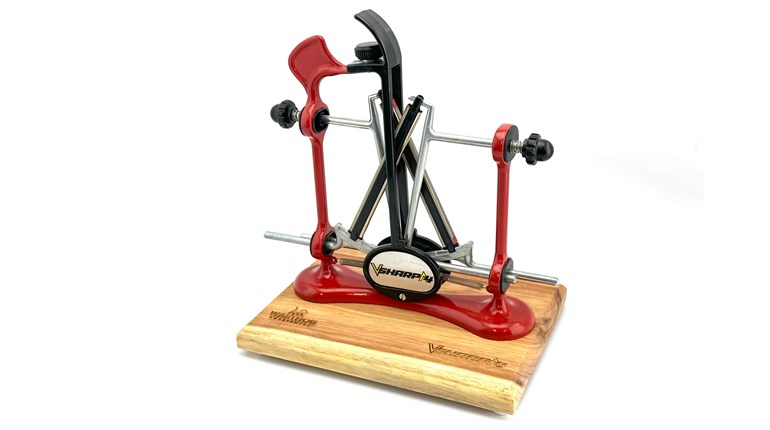

I didn’t have to acquire any 5.7-specific reloading tools to complete the work, as I had a set of Hornady dies leftover from a .22 WMR reloading project (don’t ask). One tool I was glad to have on hand was the RCBS MatchMaster powder dispenser. This tool dumps powder to within two-hundredths of a grain, which is important when you want to undergo load development in increments of just one-tenth of a grain. If you don’t already have one, you are going to want to invest in a headspace tool, as the firing process relocates the cases’ shoulders significantly. This tool will help you confirm that they have been resized back to the proper dimensions, saving your fingers and your gun from a potential rupture.

Before resizing the cases, I rolled them across a traditional lube pad. At this time, I witnessed the Lyman claim of “up to .050 inch” of shoulder displacement and checked every case after it was resized. The Hornady dies pushed it back where it was supposed to be, but I noticed a slight roundness to the shoulder. Using the headspace gauge, I confirmed that the resized cases measured the same as the ones belonging to the factory rounds. The cases also chambered without any extra effort so I wasn’t too hesitant about using them. Unfortunately, I lost even more of the polymer to the die during the sizing process, leaving me some cases with almost no coating left.

I skipped the typical accurizing steps such as flash-hole deburring and primer-pocket uniforming because I didn’t believe either of these firearms would reap the benefits of these steps. I was also skeptical as to if the rounds would even work, so there wasn’t any point in working on accuracy when function wasn’t yet guaranteed. I did, however, remove a military crimp from most of the cases and even trimmed a great deal of them.

Dropping powder was effortless in Match Mode on the RCBS dispenser. I started at the minimum of 4.3 grains of Vihtavuori N340 and, in .1-grain increments, created loads up to 4.7 grains, just shy of the 4.8-grain recommended maximum charge weight. That’s pretty aggressive for me—I usually stop much farther away from the max—but with only six-tenths of a grain to work with, this made sense. All bullets were seated to give a cartridge overall length of 1.590 inches with just a small amount of crimp to keep them in place during feeding and recoil. When finished I fit them neatly into an ammunition box intended for .38 Spl. and hit the road.

Range day afforded me just the right conditions for testing experimental rounds with light bullets. Cool 58-degree weather with little to no wind is exactly what I aim for when testing new cartridges, and this day did not disappoint. I started my testing at the 50-yard line with the 16-inch CMMG conversion upper. To my surprise, all of my homemade rounds ran pretty well. Except for just one failure to eject at the 4.5-grain mark, all other rounds cycled without issue, even those without any polymer coating at all.

While function was decent, consistency was not. I didn’t bother getting the chronograph out, as the change in velocity from round to round was so pronounced, it was evident in recoil. Despite that fluctuation, however, accuracy was still respectable, with the best group of 1.12 inches at the lighter 4.4-grain mark. This outperformed the bulk practice ammunition I used earlier by more than an inch at this distance.

On the 25-yard pistol range, I tested the Ruger-57 with the same loads. At 4.4 and 4.5 grains, the Ruger choked with a complete failure to cycle. Extraction took a bit of effort in both of these failures, and both instances involved a case with next to no polymer coating left. Later on, as I approached the two maximum charges, I had this failure more frequently. I got everything to work for the short term and achieved a best group of 1.37 inches, again better than standard factory ammunition. This group was also created with the lightest powder charge, thus avoiding any of the cycling issues experienced with the heavier loads.

So, is it all worth it? Well, it depends on the shooter and how much they enjoy reloading. With increased demand for 5.7x28 mm, ammunition manufacturers are creating new offerings, and the rejuvenated supply is likely to lead to a price drop on factory ammo. In the future, I am going to test a few other factory offerings and likely settle on one, but like everything else that I shoot, I’ll save the brass—just in case.