** When you buy products through the links on our site, we may earn a commission that supports NRA's mission to protect, preserve and defend the Second Amendment. **

The height of the Mod-0 chassis’ spring-loaded cheekpiece is adjustable.

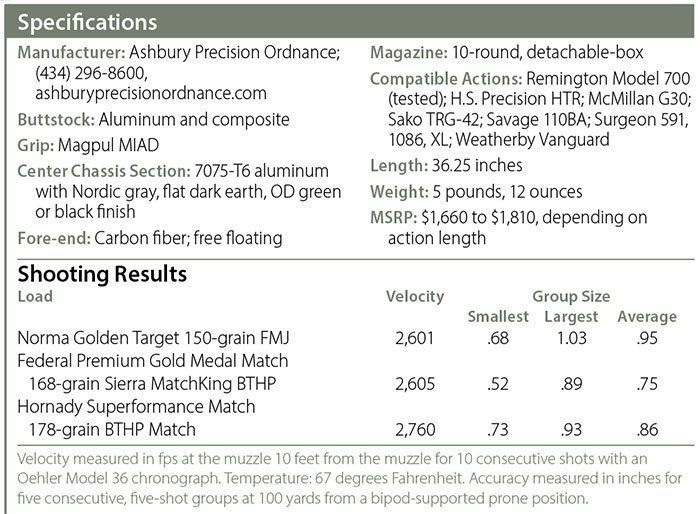

The premise that correct rifle fit leads to greater accuracy is part of the reasoning behind the SABER-FORSST Modular Rifle Chassis from Ashbury Precision Ordnance (APO) of Charlottesville, VA. With several user-adjustable features, the chassis can turn an off-the-shelf rifle having factory-determined dimensions into one that unites with your body every bit as precisely as a custom-built gun.

Length-of-pull adjustments come by way of adding or removing spacers to the buttstock. The spacers and recoil pad slide vertically in a T-shape track, permitting changes to their position.

Installing a barreled action into the Mod-0 chassis is a simple, drop-in affair. First, though, separate the fore-end from the chassis by removing two screws. Place the barreled action into the center section, snug the action screws, and slip the fore-end over the barrel to re-install it. Finally, tighten all the screws to the torque setting recommended by APO. If you have a stripped, barreled action ready to go, the process takes less than 15 minutes.

Adding or removing spacers to the buttstock by using a 3⁄16-inch hex wrench permits adjustments to length of pull. The same wrench allows users to tailor the vertical position of the sliding Limbsaver recoil pad. No tools are required to change the height of the composite cheekpiece; just turn a bolt equipped with a D-ring for easy manipulation.

Shooters can specify a paddle-type magazine release be added to the chassis just forward of the trigger guard for quick access when reloading.

The SABER-FORSST chassis promotes accuracy beyond just ergonomic improvements. CNC-machined from aluminum, the center section precisely and solidly holds the receiver for repeatability between shots. An aluminum chassis just doesn’t flex like a stock made from wood or even some synthetic materials. There was more than 5 square inches of contact between the chassis and the Remington Model 700 short-action receiver I used for testing. With the action screws torqued to 65 inch-pounds, it was one stiff setup that resulted in impressive consistency on the range.

Another benefit of the Mod-0 chassis is it provides more options for mounting optics and accessories than the stocks found on most factory bolt guns. The carbon-fiber fore-end that APO calls its Quattro design is equipped with threaded inserts along the top and bottom for attaching sections of Picatinny rail.

The barreled action I paired with the chassis for evaluation came from a Model 700 SPS chambered in .308 Win. Out of the box, the rifle produced five-shot groups that averaged 1.27 inches. I wanted to see if switching the no-frills synthetic stock with the APO chassis would make a difference. Better ergonomics were immediately noticeable, as was the added weight of the chassis. It felt like a different rifle, and it shot like one, too. Using the same loads I fired from the factory rifle, the 700 in the Mod-0 chassis cut more than .4 inch from its average group size, becoming a solid, sub-MOA rifle.

Ergonomics certainly played a part in improving the accuracy of the rifle, but I’m sure the more rigid and consistent platform the chassis provided for the barreled action also had a role. Either way, there’s little doubt the SABER-FORSST Mod-0 chassis from Ashbury Precision Ordnance raises the performance level.