The popularity of sound suppressors, or silencers in BATFE parlance, has been on a steadily rising trajectory in recent years. According to figures published by the Washington Free Beacon and BATFE, between 2017 and 2021 approved silencer registrations increased from 1.3 million to slightly more than 2.6 million. That’s impressive, but a recent analysis of BATFE’s numbers by the National Shooting Sports Foundation finds that between May 2021 and July 2024, registered suppressors have further increased to 4.86 million. That’s astounding.

While this is good news for shooters’ ears, neighbor relations and suppressor manufacturers, there’s at least one piece of baggage that accompanies these increases. I can’t quote any hard numbers, but it’s reasonable to presume that as suppressor ownership and use increase, so do the instances of projectile strikes on baffles or end caps. Anecdotal reports from within the industry and the increasing number of requests for baffle-strike help that I’ve received over the past couple years seem to bear this out.

Cause and Effect

Several conditions can set the stage for this damaging and potentially dangerous problem. A suppressor that isn’t tightly attached to the rifle can easily come out of alignment with the firearm’s bore, leading to baffle strikes—or suppressors that are launched like inert rifle grenades. Fortunately, improved muzzle-device designs have made this cause far less likely than it was with the quick-detachable systems of years past.

The negative effects of “tolerance stacking” have been and remain a major contributor to improper suppressor alignment. A barrel’s shoulder, muzzle threads and face, bore axis (relative to the shoulder and threads), muzzle device and suppressor internal threads, muzzle device outer-mounting surfaces and modular suppressor adapters all have varying degrees of allowable tolerances in their designs. The resulting dimensional variations can add up quickly and lead to the suppressor and barrel bores being misaligned.

Another problem I’ve encountered is that multiple suppressors of the same model can have different alignments when mounted on the same Quick-Detach (QD) muzzle device. I’ve run into this with brands and models across the price spectrum. The issue is further complicated by different manufacturers making QD muzzle devices that are cross-compatible, but not necessarily identical in fit.

Carbon on QD muzzle devices and internal suppressor-mounting surfaces can accumulate to the point that it prevents proper seating and alignment. In my experience, this is more common on muzzle-device exteriors than it is within suppressors. These surfaces are typically designed to handle some carbon buildup, but fit best when clean.

Additionally, a surprising number of rifles come across my bench with incorrectly installed suppressor mounts. There are several variations of this problem, such as the use of crush (spring) washers, muzzle devices that are not properly torqued or that are secured by jam nuts forward of the barrel’s shoulder. These and other errors often contribute to suppressor misalignment.

It’s rare, but sometimes a suppressor simply won’t properly align on any muzzle or muzzle device. This could be due to internal damage to the suppressor body or locking system, or a manufacturing flaw. Regardless, contacting the manufacturer for service is the safest way to deal with this problem. Shipping a suppressor to a licensed manufacturer (or gunsmith) for service does not constitute a “transfer” under the National Firearms Act (NFA), so no further taxes or pre-approvals are required. BATFE does provide guidance on how to ship suppressors to FFLs for repairs, but it’s an easy process in comparison to the NFA’s burdensome and unnecessary transfer requirements.

A Pound of Prevention

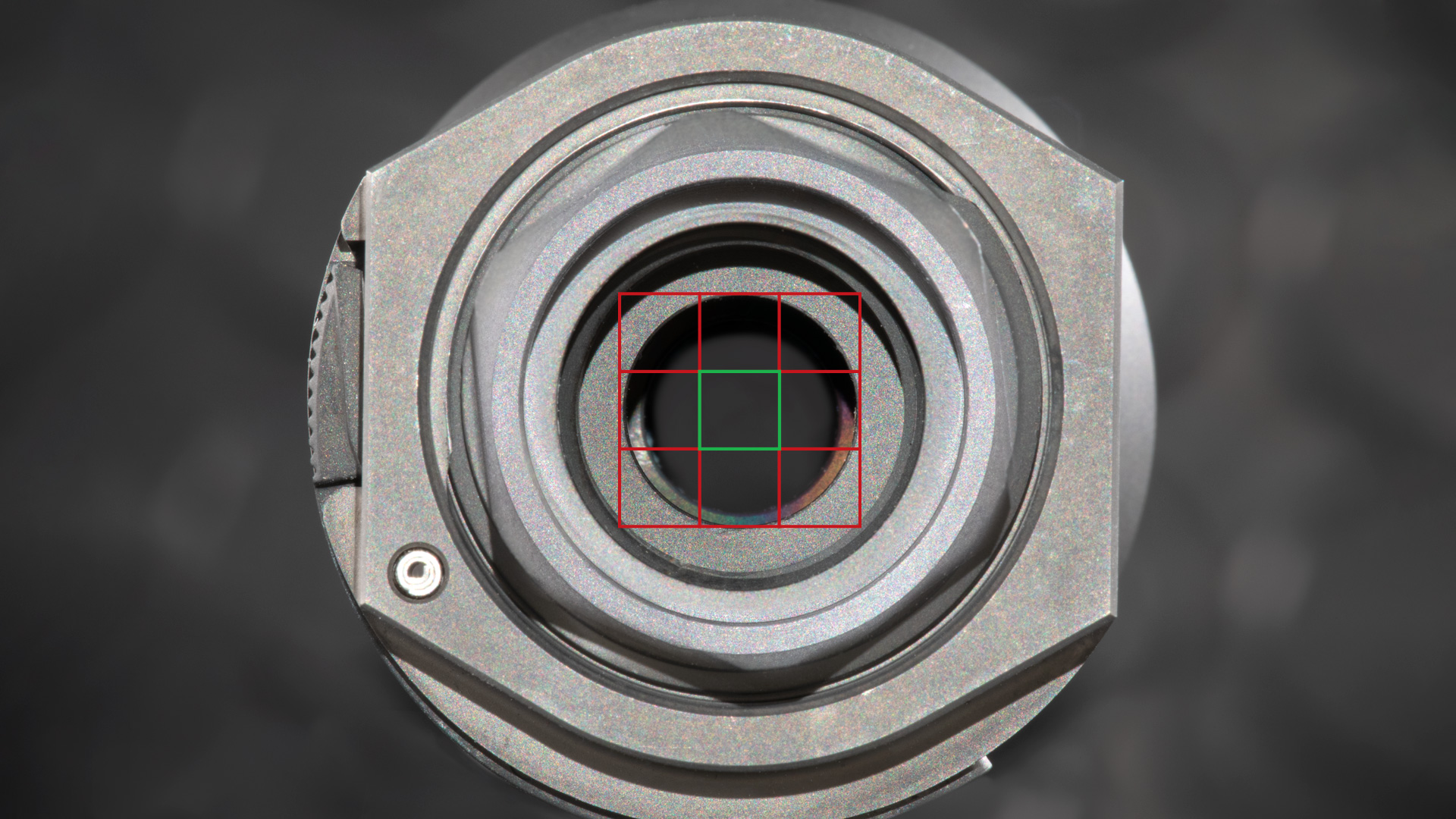

Whenever I’m building, repairing or servicing a firearm that will be suppressed, I take a series of measurements and perform several checks to ensure barrel and suppressor bores are aligned before any shots are fired through them. As most custom shops are likely to do, I use a multi-step process that requires specialized tooling and, when fixable problems are encountered, machining skills.

One critical check that just about anyone can do is to verify the alignment of a mounted suppressor with a bore rod made for the purpose. A growing number of companies offer bore-size-specific alignment rods, including Griffin Armament, SureFire, Geissele Automatics, Huxwrx and Accuracy Solutions. They’re available in stainless steel and carbon fiber, ranging anywhere from $50 to $125. Shops and gunsmiths that take muzzle-device installations seriously are likely to offer alignment-check services, too.

When verifying alignment with a rod, I start by viewing it from the front of the suppressor to confirm that the rod is well-centered. If it passes that test, I slide the rod from chamber to muzzle, through the clean bore and into the suppressor. Contact with any part of the suppressor indicates an unsafe-to-fire condition that must be investigated and remedied before use.

Periodic maintenance can help prevent problems with suppressors that previously aligned well. When I encounter carbon-caked QD muzzle devices, I clean them with a brush and solvent, paying particular attention to index slots, keyways and tapered seats. If you stay on top of it, a stiff nylon cleaning brush and carbon-removing solvent usually do the job.

For heavier deposits, I’ll use a bronze or steel-bristle brush, solvent and moderate pressure. For especially stubborn spots on muzzle devices, I use a brass wire wheel and very little pressure. The goal is to remove the carbon, not alter precision-machined mounting surfaces. I limit my clean-ing of suppressor internal-mounting surfaces to nylon brushes, shop towels and solvent only.

Even though a suppressor may line up correctly, an unstable bullet can still cause a baffle strike. Heavy-for-caliber (longer) bullets in barrels that don’t have tight-enough twist rates, projectiles with very short bearing surfaces and excessive land-to-land inner bore diameters all contribute to poor stabilization. For these reasons, it’s always a good idea to verify that projectiles fired through your rifle are making nice, symmetrical holes in paper targets before mounting a suppressor and shooting a new ammo type.

I feel safe in saying that modern manufacturing methods and better suppressor education have limited baffle and end-cap strike instances to a tiny fraction of the times suppressors are used on firearms. Still, when a new suppressor is introduced to your rifle for the first time, it’s worth ensuring their bores are in the best alignment possible.