My love-hate relationship with sound suppressors goes back many years. As a young paratrooper trying to make my way through the humid night onto a hostile Panamanian airfield, I wished for a way to conceal my muzzle flash from our less-than-friendly "hosts." Unfortunately, suppressors were not an option in the conventional Army back then.

Years later and halfway around the world, I was grateful for whatever flash and sound suppression was provided by the crude hunk of steel mounted on the end of my carbine. Today's quick-detachable (QD) sound suppressors are issued to increasing numbers of military personnel, are widely available on the commercial market and are so much better than those available just a decade ago that a fair comparison is not possible. The old ones sucked—the new ones are pretty darned good, period.

A while back, I decided to sample several 5.56 NATO sound suppressors to see how much progress has been made in recent years. I focused specifically on QD centerfire-rifle suppressors, because that is where the military market seems to be steering the commercial sector. That is not to say thread-on or integral suppressors are not effective. Both categories contain very good performers. However, QDs offer distinct functional advantages. Not only do they allow the rapid attachment and removal important for constantly changing mission profiles, but their mounts do double-duty as flash hiders and/or muzzle brakes when no suppressor is attached. Well-designed QDs also index when fully locked in place, allowing a more repeatable change from the unsuppressed zero. QDs make sense on multi-role guns not destined to be sound suppressed 100 percent of the time.

In 2006, I was tasked to find a replacement 7.62 NATO suppressor for my unit's sniper rifles. Our old models did not handle high rates of fire well and zero shifts were unpredictable. Baffle strikes were fairly common and rust was a near guarantee. I canvassed the QD-suppressor market and found I could count the number of manufacturers making serious alternatives on one hand, with two fingers and a thumb left over. The story is entirely different today. Just when I think I have all the tactical suppressor manufacturers sorted out, another pops up on the radar. That is good for the consumer, as long as everyone puts their best foot forward.

Test Methodology

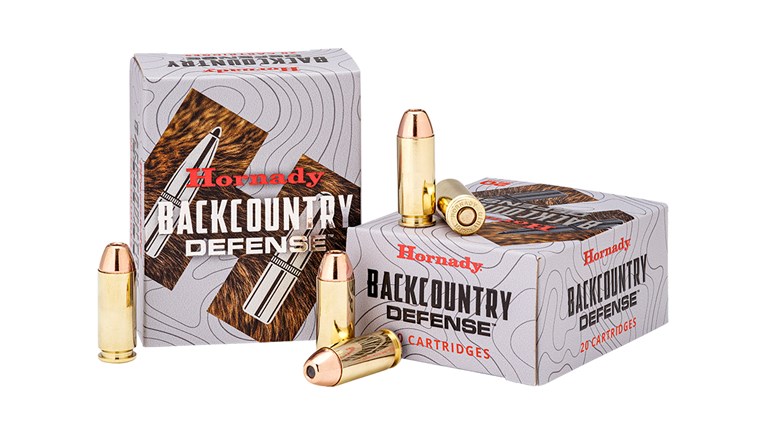

I am neither equipped for nor competent enough to test suppressors for sound-pressure level, so my evaluations were limited to the functional and ergonomic aspects of their use. Specifically, I compared four different suppressors' methods of attachment, accuracy with and without the suppressor attached, the amount of zero shift from unsuppressed to suppressed and the repeatability of that shift from one mounting to another. I also made note of muzzle velocity changes in each case. All suppressors were tested on the same rifle: a 5.56 NATO AR I built to hunt varmints, but it also likes to moonlight as a test platform. I chose two different factory loads with good track records for sub-MOA accuracy, reliability and projectile performance in this carbine: Black Hills Ammunition's 55-grain TSX and Hornady's 55-grain V-Max.

I deviated from the standard Shooting Illustrated accuracy protocol for this comparison. After zeroing, I fired a total of eight, five-round groups per suppressor and ammunition type. The groups were split between suppressed and unsuppressed, alternating with each new group. I was able to check zero-shift distances and repeatability multiple times this way. I also fired another 50 rounds through each suppressor at various ranges checking for drop values and rapid-string function. The rifle was cleaned and lubricated prior to each new model in order to level the playing field for fouling. All muzzle adapters were attached to the rifle using the manufacturers' instructions, including full curing of thread-locking compounds prior to each test.

The test rifle used a carbine-length, direct-gas-impingement operating system (DGIS) with a non-adjustable gas regulator and standard buffer and spring. During testing I found unsuppressed group size averages varied widely, depending on the type of mount attached. I included these variations in my measurements because I felt it was important to demonstrate how different muzzle-device designs can impact a gun's shootability. The baseline accuracy averages for the test rifle with a Yankee Hill Phantom flash hider/compensator are 1 inch with Black Hills' 55-grain TSX load and .82 inches with Hornady's 55-grain V-Max at 100 yards.

Quiet Zone Ahead

Times are pretty good for sound suppressor aficionados. While the NFA regulations dictating the legal transfer and ownership processes are no simpler than they have been in past years, the number of dealers and manufacturers available to help you through the process has grown and continues to grow. New suppressor designs are similarly being offered in increasing numbers, while prices drop incrementally.

The general reductions in felt recoil and sound at the muzzle are enough to make these devices useful additions to any inventory. You can place the same type of mount on several threaded muzzles and switch one suppressor between several like-caliber firearms. I use a 7.62 NATO can on .308 Win., 7.62x39 mm and 6.5 mm ARs in my own inventory. Setting aside convenience, the tactical advantages provided by a reduction in audible and visual signatures cannot be overstated. It is no coincidence the number of suppressors issued to U.S. military personnel is rising steadily. When used properly, these devices are practical and effective.

For detailed information and test results on the tested suppressors, click here for the SureFire Mini-BK, here for the AAC M4-2000 and Mini-4 and here for the Gemtech G5.