Aside from having read Homer's "Iliad" and "Odyssey" long ago, my knowledge of Greek mythology is limited to a few key characters. The aquatic beast Hydra happens to be one of those. The thought of a multi-headed serpent has staying power in my brain. Once you get to know MGI Industries' Marck 15 multi-caliber AR system, the rationale behind its choice of the Hydra moniker becomes apparent. It is not your average black rifle that only allows swapping of upper receivers and other parts to change calibers. This system allows the user to change the barrel in less than a minute and do a full caliber conversion in less than two. The ancient Greeks believed cutting off one of the Hydra's heads would bring two more. With the Marck-15, the lines between fact and fiction continue to blur.

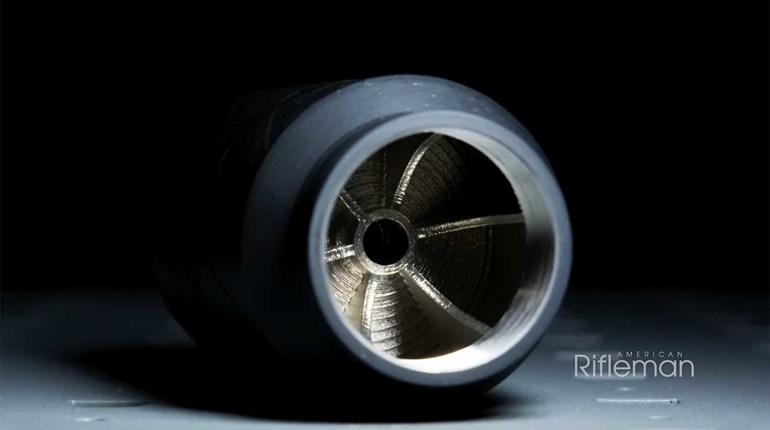

Mack Gwinn Jr.'s inspiration for the Hydra goes back to his service with the Special Forces in Vietnam. The founder of the original Bushmaster Firearms, Gwinn's fingerprints can be seen throughout the tactical-firearms market. I can definitely relate to his original desire for more mission adaptability in weapon systems through my own overseas experiences in uniform. Quick barrel changes are particularly interesting to me, so I was happy to receive a Hydra system that included all the parts necessary to shoot both 5.56 NATO and 7.62x39 mm cartridges. I have to admit I was skeptical about whether or not MGI's system would be a practical solution to the switch-barrel challenge. Such guns typically suffer from a need for complex tools, procedures or parts to achieve a workable solution. The Hydra swims an alternate route around all those issues. For one thing, it does not require removal of the fore-end to free up the barrel nut and/or barrel. Instead of a barrel nut, the Hydra uses two locking levers (affixed to the bottom of the fore-end) that rotate 90 degrees, positioning a cam bar over each side of the barrel extension's front lip, locking the barrel securely in place. The bottom line is this system works.

Multi-caliber firearms generally require barrel, bolt head and magazine changes at a minimum. The Marck 15 is no exception, but the truly modular nature of the lower receiver is what really sets it apart. Where most switch-barrel systems are limited by the type of magazine they use, MGI designed its lower to allow for an almost limitless number of magazine wells to be swapped out. The result is an AR capable of accepting standard G.I. 5.56 NATO mags, true AK 7.62x39 mm mags and even pistol magazines—all in the same lower receiver. Here, another key difference from most modular-barrel systems surfaces: The only tool needed to change chamberings is the pointed tip of a cartridge. This or any other similar object is used to free up the trigger guard's detent pin from the removable magazine well to change it. Your fingers are the only other tools required.

The Marck 15 cartridge lineup consists of seven options as of this writing: .22 LR, .223 Rem./5.56 NATO, 6.5 Grendel, 6.8 SPC, 7.62x39 mm, .450 Thumper and .458 SOCOM. The fun does not stop there. MGI's modular lower receivers can also be mated with the company's dedicated upper receivers in pistol chamberings such as .45 ACP (configured for either Glock or surplus M3 "Grease Gun" magazines) and .45 Super Mag. This all-you-can-eat buffet of cartridge options has something to offer most shooters, especially in the tactical, defensive and competitive realms.

The sample Marck 15 I received was what MGI considers its base-model 5.56 NATO unit. Its M4 configuration includes a flattop upper, detachable-carrying-handle rear sight, fixed front-sight assembly, collapsible six-position buttstock, A2-style grip, 16-inch M4-contour barrel, A2-style flash hider and a standard trigger. One deviation from a standard M4 setup is a quad-rail free-float tube around the barrel. This accuracy-enhancing feature is necessary to facilitate barrel changes. Another change is the 3-inch-long polymer and steel contraption hung conspicuously in front of the magazine well. Here, a sliding cover retains and protects the two cam levers holding the barrel tight to the upper receiver. While appearing somewhat out of place, this funny-looking bump gave me no trouble during testing.

Before heading to the range to run the Hydra through its paces, I did a trial barrel change in my shop. I hate reading directions. Fortunately, the Hydra was simple enough for my brain to figure out. I had no trouble intuitively making the needed barrel assembly, bolt and magazine well changes. That said, the Marck 15 is shipped with good directions that will talk even an AR novice through the process. It is critical to ensure the barrel is fully locked in place prior to loading and firing the Hydra. I quickly developed the habit of giving the barrel a hard pull away from the upper receiver after rotating the locking levers in place to ensure it was properly seated. One time it was not, and came right out in spite of appearing to be locked in. That was my fault, not the gun's. Pay attention to the instructions and you will not go wrong. My first run, sans instructions, used up all of 94 seconds to do a complete conversion from 5.56 NATO to 7.62x39 mm. The process got even faster after that.

The Hydra's basic configuration is not exactly set up for peak performance on target, but that is somewhat by design. There are plenty of tricked-out, off-the-shelf ARs to choose from, but none are as adaptable to different cartridges as the Hydra. Still, I wanted to give it a good test on the range, so I used ammo and optics appropriate for the task. The 5.56 NATO barrel has a 1:9-inch twist, so I selected two solid 55- and 69-grain loads that work well in loose twist rates, as well as two 123-grain loads for the 7.62x39 mm barrel. Since I knew I'd be fighting the stock trigger while shooting for precision, I mounted a Nightforce 3.5-15x50 mm F1 scope and a Harris bipod to help with my end of the equation.

Range testing the 5.56 NATO configuration revealed no surprises. Accuracy was slightly better than normally seen in stock AR carbines when using good ammo and optics. Average extreme spread for all 5.56 NATO groups together was 1.7 MOA. I fired a total of 100 rounds using a mixture of slow-fire grouping and rapid drills at close range with iron sights. No malfunctions occurred, and the carbine handled just as any other AR carbine I have fired.

I converted the gun to 7.62x39 mm configuration on the range without difficulty and first tested that chambering via slow-fire from a prone position. I was immediately reminded of how 30-round AK magazines tend to add difficulty to prone shooting. I like to keep my torso as low to the ground as possible when firing, but in this case I had to extend the bipod's legs to clear the magazine. This is not really a problem on a firearm with which you don't plan to shoot record groups, but it is good to remember if you go prone in a hurry without a bipod or other rest. Groups with the larger-caliber chambering were akin to run-of-the-mill AK performance. As with many other rifles and carbines I complain about, I suspect a simple trigger change alone would help the accuracy equation.

The trigger pull weighed in at 7 pounds with a fair amount of creep. Overall groups for both 7.62x39 mm ammo types averaged 2.9 MOA at 100 yards. I have seen sub-MOA accuracy with U.S.-made factory 7.62x39 mm ammo in other AR platforms, so there is definitely room for improvement on this particular Hydra head, but at least it went bang every time I pulled the trigger during 90 rounds of testing. Forty of those rounds were steel-cased fodder, which often gives tighter AR chambers trouble. The Hydra chewed right through the stuff without blinking.

I am always curious to see how well a quick-change barrel system will retain zero, so I checked the Hydra on this point after shooting 7.62x39 mm groups for accuracy. Strangely, the results differed for each ammunition type. Hornady's 123-grain SST load showed no measurable shift in point of impact (POI) between barrel removals and reinstallations. However, DoubleTap's 123-grain SST load averaged a 3-inch vertical shift. I only tested a couple of groups with each ammo type, so there is not enough data from which to draw any solid conclusions. Suffice it to say, the Hydra system certainly has the potential to stay relatively close to zero if the barrel is removed for ease of transport and later reinstalled.

Just like when using AK mags in their parent platform, they do not lock the bolt to the rear after the final shot in the magazine when used in the Hydra. The MGI 7.62x39 mm mag-well adapter does not even have a provision to manually lock the bolt to the rear. That took some getting used to. I normally lock the bolt to the rear during testing to allow faster cooling between groups and to show an empty chamber while on the firing line.

I was curious to know whether I could use MGI's lower with the AK mag adapter on my own 7.62x39 mm upper. Fortunately, I looked in the accompanying manual before trying to mate the two. It turns out some machining is required to allow the higher-riding AK magazines to function in a conventional upper receiver. I elected not to permanently mill my upper for this test, so I cannot comment on the process.

I was curious to know whether I could use MGI's lower with the AK mag adapter on my own 7.62x39 mm upper. Fortunately, I looked in the accompanying manual before trying to mate the two. It turns out some machining is required to allow the higher-riding AK magazines to function in a conventional upper receiver. I elected not to permanently mill my upper for this test, so I cannot comment on the process.

I really like the pairing of this cartridge with the AR platform. Were I purchasing the base 5.56 NATO system, the 7.62x39 mm conversion package would be next on my list. The total cost for the base model 5.56 NATO Hydra and the 7.62x39 mm conversion kit is within the same ballpark as a stock AR carbine with an additional 7.62x39 mm upper. The disadvantage to the Hydra in this comparison is optics will have to be adjusted for each chambering, whereas multiple upper receivers on a standard AR will wear their own optics. However, that also makes the Hydra cheaper in the long run, because only one optic is needed and it really is not that hard to make note of scope or sight adjustments needed for different calibers. I can also testify to the fact it is a heck of a lot easier to find inexpensive magazines for the Hydra's AK adapter than it is to find similarly sized 7.62x39 mm mags compatible with standard AR mag wells.

MGI's Marck 15 Hydra should appeal to different shooters on at least one of several levels. First, it is truly modular and adaptable to a wide variety of cartridge chamberings. Second, the Hydra's lower receiver is the only actual portion that qualifies as a firearm requiring the normal transfer procedures through an FFL. Third, its barrel lock-in system appears to be a good design. So long as the barrel is fully seated and the forearm-mounted protective cover is in position over the locking levers, the barrel is tightly secured. Last, the Hydra is a simple system. No complex tools or gunsmithing knowledge are required to swap chamberings. Just follow the instructions, and you will be able to handle your own cartridge conversions in mere seconds. This is one multi-headed creature even Hercules would have been happy to have on his side.

Manufacturer: MGI Industries; (207) 817-3280, mgi-military.com

Action Type: Direct-gas-impingement-operated semi-automatic; quick-change modular barrel and magazine well system

Caliber: .22 LR, .223 Rem/5.56 NATO (tested), 6.5 Grendel, 6.8 SPC, 7.62x39 (tested), .450 Thumper, .458 SOCOM

Capacity: 30 rounds

Barrel: 16 inches, chrome-moly, M4 contour (5.56 NATO); 16 inches, chrome-moly, medium-contour (7.62x39 mm)

Rifling: 6 grooves, 1:9-inch RH twist (5.56 NATO); 6 grooves, 1:10-inch RH twist (7.62x39 mm)

Sights: Dual aperture, windage-adjustable rear peep in removable carrying handle; fixed, elevation-adjustable front-sight assembly

Trigger: Single-stage; compatible with aftermarket small-pin AR triggers; 7-pound pull weight

Stock: Six-position, collapsible M4 buttstock, A2 pistol grip

Length: 32.3 to 35.7 inches

Weight: 7 pounds, 5 ounces

Accessories: One magazine, operator's manual, optional additional caliber conversion kits

MSRP: $1,250 (base 5.56 NATO carbine as tested); $549 (7.62x39 mm conversion kit as tested)