Carbon fiber has been a viable industrial material since the 1970s. Light, strong and distinctive-looking, it's been the used in high-performance aircraft and fast cars. More recently, it became the prestigious and coveted component of super-light bicycles and portable-but-rigid camera tripods. In the past few years, it also became a material of choice for the builders of competition rifles. I decided it was time to see what this material offered modern shooters, so I tested three carbon-fiber designs.

The thermal expansion of carbon-fiber parts is half that of steel and a third of aluminum. That's a great plus for all carbon-fiber construction, but presents additional challenges to mixed-metal and composite designs. The same challenges are, of course, present whenever any two materials are mixed in an area subject to intense heat. More important for the shooters, carbon fiber conducts heat half as quickly as steel and nearly 10 times slower than aluminum. That makes a carbon-fiber freefloat tube much easier on the hands than one made from metal, not to mention significantly lighter weight. Wood insulates even better, but a much greater thickness is required for the same strength. Carbon fiber is a definite winner in this regard, being as strong as Kevlar and far ahead of metal and wood. Even a thin tube is extremely rigid, making it an almost ideal material for buffer tubes, fore-ends and barrel wraps. That smoothness and unidirectional rigidity is what makes carbon-fiber cleaning rods possible as well.

Why hasn't this wonderful material taken over from metal for everything? Cost is one reason: carbon-fiber composites are expensive. Fraying of the fibers at the ends of parts is another concern, to the point where some rifle makers tip fore-ends with aluminum caps to guard against damage. The production and tooling challenges also play a role—going through carbon fiber uses up drill bits, fast. The insulating quality of the material is terrific for hunters who don't subject their barrels to intense heat, but unhelpful for high-volume shooters whose barrels must radiate heat efficiently to avoid damage to rifling.

Carbon-fiber strength is very directional, so the same buffer tube that resists recoil impulses flexes enough to deliver a jolt to the cheek every time the buffer passes within. A Neoprene wrap fixes that problem, but the rifle builder has to be aware of the issue. Fatigue resistance is good, but failure can be quite sudden, which is why we do not see carbon-fiber receivers. And, finally, relatively few manufacturers know how to work this material to maximize its advantages and not run afoul of its weaknesses.

The MAG Tactical AIR15 family of super-light defensive rifles uses a carbon-fiber fore-end around a super-light barrel, matched to a low-mass bolt and carrier in a magnesium-alloy upper and coupled with a magensium-alloy lower. The goal achieved is a 4.8 pound—with an Aimpoint Micro T1 sight included—fighting tool that doesn't cut corners on performance. Testing showed substantially better heat endurance than expected from such a thin barrel, most likely because of the excellent air flow around it. The muzzle brake permanently attached to the 14.5-inch barrel was not particularly noisy, yet quite effective in delivering felt recoil similar to the heavier M4 carbine. The sole design omission found was the absence of a short rail up front for a folding backup sight and a sling eyelet. Designed for fast, mainly short-range engagements, this remarkably handy carbine delivered 3-MOA accuracy with 55- and 62-grain ball ammunition using the unmagnified sight, and 2.3-MOA with 69-grain match ammo and a 4X scope. Every single person who handled the AIR15 remarked on the excellent balance and light weight. The main benefit of carbon fiber was in the enabling the extension of the fore-end far enough out for muzzle control without shifting the center of gravity too far forward as a metal fore-end would have.

The Houlding Precision Firearms Wraith is a full-size competition rifle with a full-length carbon-fiber fore-end around a freefloat barrel and a simplified stock on a carbon-fiber buffer tube. The material choices were dictated as much by the desire to drop the weight to a mere 6.2 pounds as by the imperative to reduce heat transfer to the shooter. The low-vibration nature of the material and octagonal cross-section also makes it possible to fire the rifle with the fore-end resting on a support and not experience a drastic change in the point of impact. The fore-end tube is capped with aluminum to make it less susceptible to damage during fast-paced 3-gun matches. Equipped with a low-mass bolt and carrier, the Wraith has minimal felt recoil. The aggressive compensator helps to control muzzle rise, at the cost of considerable reflection off lane dividers or cover. I would have preferred a less aggressive muzzle device and a deeper, more absorbent buttstock instead for placing support hand in prone firing, but professional shooters are running this rifle as configured with excellent results. Geissele's Super Dynamic 2.5-pound flat-front competition trigger makes accurate shooting a snap, with most loads turning in around 1-MOA groups. Interestingly, though, the rifle favors heavier bullets overall, 55-grain moly-coated match loaded by Black Hills consistently shot the smallest groups. Despite the medium-weight barrel, the 16-inch carbine can be run with one hand without undue fatigue. The balance improvement comes mainly from the weight savings afforded by the octagonal carbon-fiber tube. The fore-end was initially available in KeyMod configuration, but an M-LOK version was added on customer request. Unlike most highly skeletonized metal tubes, it is smooth and easy on the hands, while retaining enough friction not to slide around during firing.

Lancer Systems' L15 "Heavy Metal" 3-gun .308 Win. rifle has a medium profile stainless barrel which dominates the look and the balance of the firearm. While not particularly heavy at 9.5 pounds, it's front-balanced and feels heftier than it actually is. A heavily ventilated carbon-fiber fore-end equipped with a short rail for backup sights keeps the barrel cool and the shooter's support hand free of abrasion. Unusually, the buttstock is sculpted into a complex but comfortable shape, well suited for either unsupported or prone firing. The light weight of the stock is a stark contrast to traditional High Power rifles with lead weights in their stocks: Lancer designers correctly figured the weight of user-added optics into the balance. With the tank-like Sphur mount holding both the massive 34-mm-tubed Nightforce ATACR 5-25x56 mm scope and an offset Trijicon RMR fiber-optic red-dot backup, the full-up loaded weight goes to 13.9 pounds and the balance becomes perfectly neutral around the magazine well. The Sphur mount mechanical auto-leveling feature proved itself immediately, reducing the time required to install the optic to about one minute. Predictably, with match ammunition and a solid rest, anything over .5 MOA with match ammunition could be safely attributed to user error. Between the rifle's weight, the effective but inoffensive muzzle brake and the smooth, well-sculpted carbon-fiber furniture, the L15 was more pleasant to run than most smallbore guns. Its L7AWM 20-round magazines deserve a special mention—released around the same time as the .308-caliber rifle family, they come in translucent and opaque variants, both with stainless steel feed lips. Combined with the flared mag well of the L15, they were easy to insert even with the bolt forward, had no play once seated and fed all bullet profiles with boring reliability.

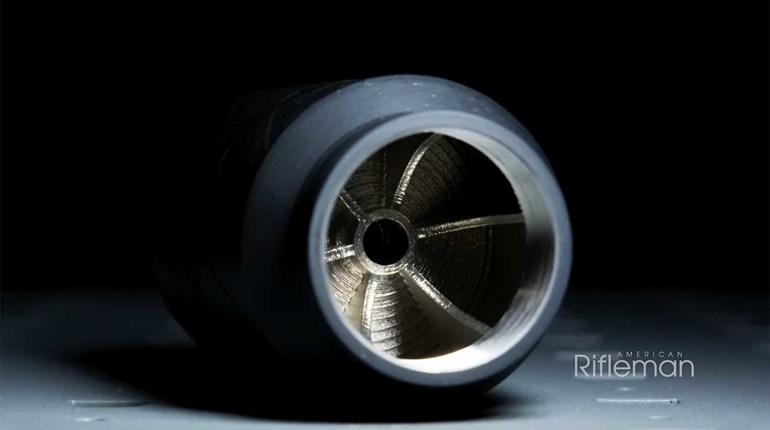

Summing up the carbon-fiber aspect of these three rifles, we see weight saving, insulation from heat and reduction of abrasiveness as the main uses for this material. Cold-climate marksmen would also appreciate that carbon-fiber doesn't feel as cold to the touch as metal, and tropical commandos would enjoy freedom from rust. As the manufacturing-knowledge pool expands, we can expect to see a more purposeful use of carbon fiber parts for such tasks as barrel vibration-reduction or unification. Carbon-fiber sound suppressors for shotguns were rolled out by UTAS this year, benefitting from both light weight and resistance to cleaning cheamicals. I wonder what the next year will bring.