Lost somewhere in marketing hype, gunwriter drivel and Hollywood’s characterization of handguns, you’ll find the true definition of a fighting pistol. Pundits and self-proclaimed experts can pontificate all they want about what makes a fighting handgun, but nothing can define it better than history. Many preach and argue the virtues of the 1911 and the Glock, and even pit one against the other, while overlooking what might be the most extensively used fighting pistol of all time: the Browning Hi Power.

Students of firearms history know blunders have been made during the selection of small arms by the military and law enforcement. They also know these selections were often the product of savvy marketing schemes and, well, politics. Resumé wise, few handguns can compete with the Hi Power.

In the 1920s the French military decided it needed a compact handgun with a minimum capacity of 10 rounds. Desired features included a magazine disconnect, a positive safety and an external hammer. The pistol also had to be simple to field-strip and assemble, weigh less than 1 kilogram (2.2 pounds) and be lethal at 50 meters.

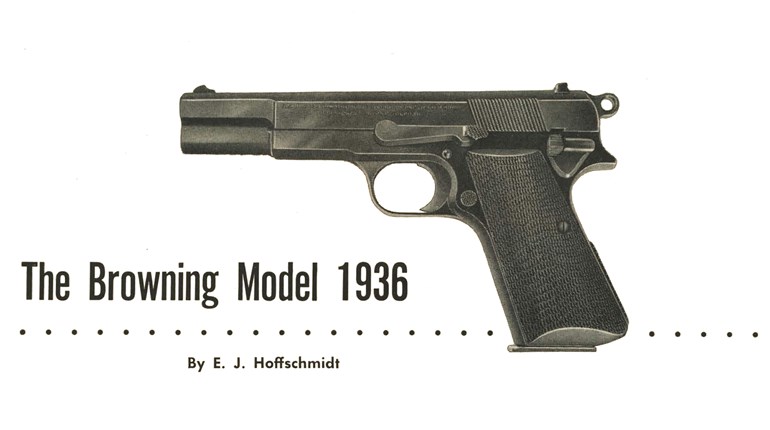

Belgian arms maker Fabrique Nationale commissioned American John Browning to develop this handgun, but he died before the project was complete. It would be nine more years—1935—before the bushingless, single-action, 13-round semi-automatic known today as the Browning Hi Power was complete. The pistol, commonly referred to as the P-35, was immediately adopted by the Belgian military. The French called it the Grande Puissance, which means “great power,” but ironically, after commissioning its development, chose a different handgun. The French! Go figure.

Since then, the Hi Power has seen service with the British, Germany during World War II, the U.S. Office of Strategic Services, FBI SWAT and countless other militaries and police agencies, as well as the Irish military, which simply called it the BAP (Browning Automatic Pistol). The Hi Power is also one of the few handguns which has been used by opposing forces in battle.

Not Quite Perfect

A defensive handgun should be user friendly and easy to maintain, while providing combat accuracy and reliability. It should not be so heavy it pulls your britches below your butt cheeks. All these things can be said about the Hi Power. Maybe most importantly, if you hand someone a Hi Power, their first comment will be, “Hey! That feels really good!” The Hi Power’s grip is one of the most ergonomic designs to grace a handgun, ever.

The Hi Power is also relatively light, especially when compared to a fully loaded 1911 in .45 ACP, which weighs almost 3 pounds. A fully loaded Hi Power weighs a bit more than 2 pounds. Interestingly, a Hi Power magazine stuffed full of 9 mm cartridges weighs about the same as a 1911 magazine carrying a full capacity of .45 ACP rounds.

I’ve owned several Browning Hi Powers but never managed to keep one in a holster very long. There are a couple reasons for this. Hi Powers are not known for great triggers. Typically, pull weight on a factory Hi Power will range from 7 to 9 pounds. The magazine disconnect, which prevents the pistol from firing unless a magazine is in place, is the culprit. Also, if you shoot with a high grip, the factory hammer will bite the web of your hand. I know, a fighting man—any man—should be tough, but there’s no reason shooting a handgun should be painful.

You can argue the merits of a magazine disconnect on a defensive handgun all you want. You can also wear gloves or just act tough when you shoot. But the bottom line is the bad trigger and the constant pinching will turn you off, and you’ll trade your Hi Power for a Glock. (Hey, we all occasionally make bad decisions.)

Improving an Icon

A year ago I was visiting with Robbie Barrkman of Robar, and the talk turned to Hi Powers. After I relayed my experiences, Barrkman told me he would correct these shortcomings and further tweak the pistol, guaranteeing it would be a handgun I’d hold on to. So I ordered a new Hi Power, ran about 200 rounds through it to confirm it was sound and then shipped it off to Robar.

First, Barrkman removed the magazine disconnect, installed a Wolff spring kit and worked the trigger to a blissfully smooth 4.25 pounds. He also swapped factory components for a Commander-style hammer and a Cylinder & Slide safety. The new hammer would prevent the pinch, and the new safety replaced the factory ambidextrous version, which bit into the first knuckle of my shooting hand. Barrkman then dehorned the sharp edges, and performed a superb stippling job on the frontstrap and backstrap to enhance the already comfortable grip.

With the intricate work done, Robar coated the slide and frame with its new Poly-T2 finish in gunmetal gray. Poly-T2 is a PTFE-based, modified-epoxy coating that offers unbeatable corrosion resistance and is as silky smooth as satin lingerie. Really! I cannot think of a better way to describe it. The pistol’s other components, including the slide lock, safety, hammer, trigger, all internals, both magazines and the barrel, received a silverish NP3 finish, a treatment that combines electroless nickel with PTFE. The pistol is business like or beautiful—maybe both.

The sights were another element requiring attention. I despised the sort of three-square-dot affair from the factory, partly because I feel the rear sight need not attract unnecessary attention and partly because my aging eyes need sights that are easier to see. All my 1911s are fitted with the XS Sight Systems 24/7 Big Dot or Standard Dot up front, and I wanted to go that way for my Hi Power. However, the standard XS rear sight for the Hi Power is just a simple, unsexy wedge, and I prefer the Novak-style rear sight. Charles Daly worked with XS a few years back to offer improved sights on the Hi Power clone it manufactured. I contacted Bo Wallace at XS and asked if he had a set of these. As it turns out, the sights on the Charles Daly version of the Hi Power were just 1911 sights. On a Hi Power, however, the rear sight is set at a slightly different height, so Wallace contacted Barrkman to make sure the cut in the slide was correct for the XS rear.

While Barrkman was working his magic, I was thinking about grips. I wanted something unique and, while considering various wood stocks, I ended up on the phone with Ed Strange from Wicked Grips. Strange told me about a new process where the company can take any photo and anodize it on aluminum grips. I thought this was really cool, envisioning various designs like vintage World War II aircraft-nose art and even a photo of my wife in a bikini. Better judgment prevailed, and I opted for a photo of a pile of empty 9 mm cases, a tribute to my “Empty Cases” blog.

Better than Before

Before sending the Hi Power to Robar, I took the time to see how well I could shoot it. Offhand at 10 yards, my average for four, five-shot groups was 2.03 inches. When the pistol returned, I immediately installed the grips and, after a few moments of reveling in its beauty, stepped out to see how it would shoot.

The first 20 shots were a repeat of my pre-Robar evaluation, and the average group size shrunk by 10 percent to 1.83 inches. Why? First, the removal of the magazine disconnect, installation of the new spring kit and benefits of the trigger job reduced pull weight while making the trigger smooth as snot. Second, I could see the XS sights better than the originals, even without my prescription shooting glasses.

Next, I ran the pistol through various drills. Working from a Galco Avenger holster, I put the pistol through my standard evaluation drill, the Forty-Five. This drill consists of shooting five shots into a 5-inch circle at a range of 5 yards, with a par time of 5 seconds. My average time was 3.16 seconds, which was about a half-second faster than I could run this drill with the pistol before Barrkman’s work. My average with the revamped Hi Power was also a half-second faster than my average with a Commader-size 1911 in .45 ACP. Obviously, the reduced recoil of the 9 mm loads helped me achieve the faster average time, which was fairly consistent throughout the other drills I performed.

I also fired the Hi Power from a rest at 25 yards with three different loads. This is something I only do when obtaining formal accuracy results, for I feel it has little or no importance in regard to a defensive handgun. Over the years, I’ve found my offhand groups at 10 yards are generally representative of what I can expect to do with a pistol at 25 yards from a rest. This again proved to be the case; the custom Hi Power averaged 2.19 inches for five, five-shot groups with three different loads at 25 yards.

The pistol has also proven to be unfailingly reliable. With the exception of the CCI shotshells I rely on for snake defense—which in 9 mm pistols commonly do not fully cycle the slide—there has not been a single malfunction of any sort. This is a slick-running, slick-looking pistol that will eat just about anything I want to feed it.

So what’s a 1911 guy going to do with a Hi Power too good to get rid of? Carry it and shoot it. After all, the Hi Power, like the 1911, is a single-action semi-automatic with a thumb safety that locks the slide in battery. And, unlike wives, handguns don’t get upset if you fool around with another pistol on the side, especially considering the 1911 and the Hi Power are kind of in the same John Browning family. I’m sorry; as a hillbilly from West Virginia, I probably should not have said that.

Bottom line, the Hi Power is a fine pistol if it gets a bit of tweaking. It’s not new, it’s not plastic and it’s not all that trendy. But it does have the distinction of being a pistol that has been used by more soldiers than most others in the world. Some things happen as the result of slick marketing, political influence and even accident. Not that.

Custom Cost

What does a refined Hi Power like the one from Robar cost? Like most things in life, the good stuff is never free. Expect to pay between $800 and $1,000 for a new Browning

Hi Power (MSRP is $1,059.99). You can get a used pistol or a reproduction from lesser-known manufacturers for a bit cheaper. The total cost for parts and all the work Robar did on my Hi Power was $1,390. Add in the custom Wicked Grips for $125, and you’ll approach $2,500. Of course, you could alter the build as you see fit. Foregoing the stippling and the metal finishes would save $665, and both are something you could have Robar do later.

Cylinder & Slide safety (parts and labor) $108

Commander-style hammer (parts and labor) $101

Dehorn $80

Stipple frontstrap $175

Stipple backstrap $175

Wolff spring kit $13

Front and rear XS Sights (parts and labor) $245

Apply Poly-T2 and NP3 finishes $315

Remove magazine disconnect, perform trigger job, test fire $178

Custom Wicked Grips $125

TOTAL $1,515

(Prices subject to change.)