At last we get away from the minutia and have arrived at one of the most-critical elements of any firearm build: the barrel. While the process doesn’t appear complicated, this is where the rubber meets the road, so attention to detail is important—lest your rifle not shoot true—leaving you with nothing more than an over-priced paperweight. The necessary parts and tools are listed below:

Parts

Barrel

Barrel nut

Tools

Barrel wrench or related multi-tool

Brownells upper-receiver action block with insert

Torque wrench with 1/2-inch driver

Bench-mounted vise

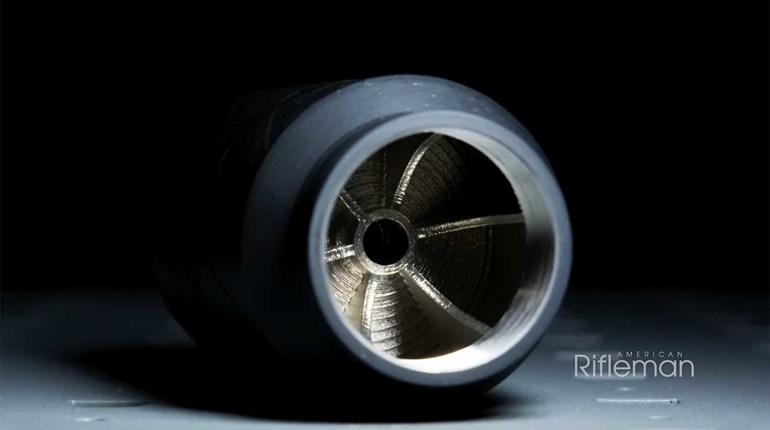

When it comes to selecting features for this build, I decided early on that I would only choose those that aligned with its hunting purpose. Taking into consideration that my disability doesn't afford me the luxury of movement, the alternative of hunting from a permanent stand brings certain perks with it, such as being partially shielded front the elements and especially a padded shooting rest. The latter of which allowed me the freedom to take full advantage of the higher velocity, flatter trajectory (and the added dependability of a rifle-length gas system) of a 24-inch barrel—without fear or it becoming unwieldy or compromising my maneuverability. As an added bonus, the medium-contour model I selected from Brownells included its own caliber-specific bolt. (I know someone who used a shorter version of the same barrel for an AR build with good results, which influenced my decision though his gunsmith later urged me swap it out for an Alexander Arms bolt, without going into detail.

The Geissele Automatics freefloating fore-end I chose for this build came with a barrel nut. The following instructions are for installing the barrel using this hardware and are typical for fore-ends of this type. However, the process may vary with similar offerings.

Slide the action block insert inside the receiver to support it and prevent distortion under pressure as you install the barrel. Then, clamp the receiver in the action block, and secure both in a bench-mounted vise.

Clean the receiver threads with a small brush, and coat them with an anti-seize compound or high-quality grease. Next, insert the barrel through the front of the receiver, and thread the barrel nut onto the receiver with the wide, threaded portion to the rear. Tighten the barrel nut using a barrel wrench/multi-tool. The Multi-Tool is designed to be used with a ½ -inch-drive torque wrench. The mil-spec technique is as follows: Torque to 35 foot-pounds (ft.-lbs.). Loosen.

Torque again to 35 ft.-lbs. Loosen again. Torque past 35 ft.-lbs. until the next hole in the nut aligns with the gas-tube hole in the receiver—do not to exceed 80 ft.-lbs.

During a phone conversation I had with Bill Alexander of Alexander Arms, prior to installing the barrel, he suggested that I add a thin coat of Locktite #243 to the exterior of the barrel's extension and the the inside of the receiver as a means of lessening the greater harmonics associated with extra-long barrels.

But that is by no means the most unique facet of this stage of the build. Jay's barrel shipped with a proprietary torque wrench that sported quite a short handle. As a means of compensating for it, the manufacturer's directions suggested incorporating a 1- to 2-foot section of galvanized pipe as a means of garnering more torque. While such an accouterment is hardly standard gunsmithing gear, the hefty addition allowed Jay to easily dispatch the task at hand...in the Firearm Inventory Manager's Office...with the pipe. With fun like this, who needs board games?

In the next installment, we’ll cover installing the fore-end.