The M16/AR-15 family of firearms has gone through many changes during its decades of faithful service to our military, law enforcement and civilian shooting communities. One early modification was the addition of a Forward Assist Assembly (FAA) to the M16A1 variant. The original M16s and AR-15s lacked a way to positively push a bolt into battery, which did not entirely suit military folks who were used to rifles like the M1 Garand, M1 Carbine and M14. The reciprocating charging handles of those more-familiar semi-autos could be pushed forward to assist a bolt’s final movement into battery, if necessary. I can understand why losing this ability might have been one radical change too many for decision makers of the era, who were already grappling with a .224-bore rifle made largely of aluminum and plastic. But, was the forward assist actually needed or was it an answer in search of a problem? As with just about every other aspect of firearm-component design and use, the answer you get depends on whom you ask.

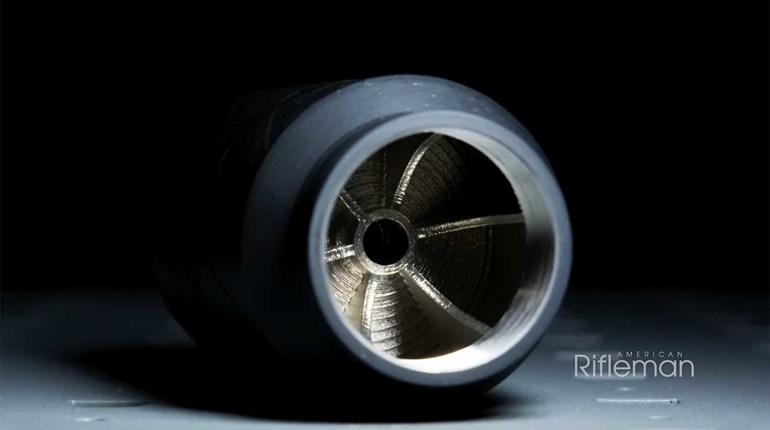

The whole idea of the Forward Assist Assembly is that if a bolt doesn’t fully close, the shooter can push or strike the outer button to drive the bolt into battery. The FAA is essentially a lever disguised as a button, inserted through the right-side wall of an AR’s upper receiver. A diminutive, .068-inch-diameter roll pin connects the FAA’s halves and functions as a hinge for the articulating, front pawl section. A nested coil spring inside the receiver’s FAA port keeps the pawl from impinging on the bolt carrier until the FAA is pushed. A larger roll pin fixes the assembly inside the upper receiver. To get the most out of an FAA’s leverage, scallops are cut on the right side of the bolt carrier, into which the pawl fits as a carrier is incrementally driven forward by hand. Many large-frame, DPMS/LR-308-pattern guns have FAA’s positioned high on the receiver and out of alignment with the carrier’s scalloped area. When pushed, these high-mounted FAA’s impinge on a solitary bolt-carrier edge during the final stage of forward movement.

During Army basic training I was taught to use the SPORTS acronym to provide immediate action in the event of a stoppage in my M16A1 rifle. That stands for Slap the magazine, Pull the charging handle rearward, Observe what gets ejected and that the chamber is clear, Release the charging handle, Tap the forward assist and Squeeze the trigger. While these steps did not remedy all malfunctions, they nonetheless gave us young grunts a place to start in an easy-to-remember format. Ironically, “tapping” the FAA rarely gets the job done on an out-of-battery bolt. The only time such a push actually works is when other methods of closing the bolt would also work. A common technique is to slightly retract the charging handle and then release it so that the action spring can help the bolt fully seat. Less-common is simply using a thumb to nudge the visible portion of the bolt carrier forward. The FAA is more useful when the bolt has a tougher hang-up. A firm palm strike to the FAA’s round or elongated button end may or may not do the trick in this case. That leads us to one of the chief problems with an FAA: Stoppages are often caused by problems too complex to be solved by simply hammering the bolt into battery. Blown primers are a great example. It will do you no good to force a bolt closed if a primer is lodged in the locking-lug area. A good rule of thumb with any rifle is that if you have to beat the bolt closed, you should not pull the trigger.

Another strike against the FAA is that the tiny roll pin holding it together is the weakest link in its design. Shear this pin by getting too aggressive in your “tapping” and the front half of the FAA will wedge itself between the bolt carrier and the upper receiver wall, causing a problem that will take your AR out of the fight. I have seen this happen twice—once during an Army test and once in a gun brought into my shop for repair. Both instances required removal of the lower receiver’s buffer tube in order to dislodge the partially retracted bolt carrier and separate the receivers for repair.

All of my current small-frame ARs have forward-assist assemblies, but only because the uppers were built for them. Some of my Army ARs did, but those I used most heavily in wartime did not and that was never a problem for me. I am positive there have been cases where FAAs have successfully closed hesitant bolts in the heat of battle. But, in 30-plus years of shooting ARs, I can count on one hand the number of times I have used an FAA to successfully get a gun back into operation. That only happened in training and in hindsight I could have had the same success without using the old palm buster.

Lest anyone think that the perceived need of forward assistance is limited to ARs, remember that reciprocating charging handles on modern guns like the FN SCAR, Benelli MR1 and IWI Galil are likewise intended to provide a means of manually assisting the bolt. Other guns, like the Remington (Bushmaster) ACR and LWRCI R.E.P.R., have forward-assistance features designed into non-reciprocating charging handles. Side-charging ARs are also an option for those folks who do not mind a reciprocating charging handle. Cocking handles machined into the bolt carrier, such as with the AK family, are strong enough to withstand very hard “coaxing.” But, the same conditions that hinder a traditional AR forward assist’s usefulness will cause troubles for these other guns, too: A bolt that needs that much help closing likely has a bigger problem.

Until someone designs a stout, forward-driving, non-reciprocating AR charging handle that can be dropped in without modification, a large number of AR upper receivers will continue to be built to house Forward Assist Assemblies. That leaves shooters to either use or ignore these slightly annoying afterthoughts as we see fit.