Above: The purpose of this group fired with the author’s 2Fity Hillbilly wildcat cartridge was not to achieve superior accuracy, but rather to meet his target velocity. To shrink groups, one can tinker with bullet-seating depth or try another powder or primer.

Handloading ammo is easy; finding a mix you and your rifle like can be hard. Handloading is like cooking. You work with various recipes to find a taste you relish. Sometimes those recipes need to be tweaked to suit your needs and one of the best ways to do this is with an established process. Here’s how I do it for my rifles:

Step 1 - Prep: Take about 50 once-fired cases from your rifle, size them, and trim them to a uniform length. Then lightly chamfer the inside and outside of the case mouths.

Step 2 - Check: Check case-neck straightness with a tool like the RCBS Casemaster. Cases with necks that are not straight tend to make bullets go in different directions. Cull any case exhibiting more than .001 run out.

Step 3 - Clean: Clean primer pockets and tumble or wash your cases in a sonic cleaner. When done, remove all the media, check the primer pockets and flash holes, and/or dry the cases in the sun or in a case dryer.

Step 4 - Prime: Pick a primer and stick with it, unless you come to believe it might not be the best one for your recipe. If you use a magnum primer, make sure you consult data established with magnum primers.

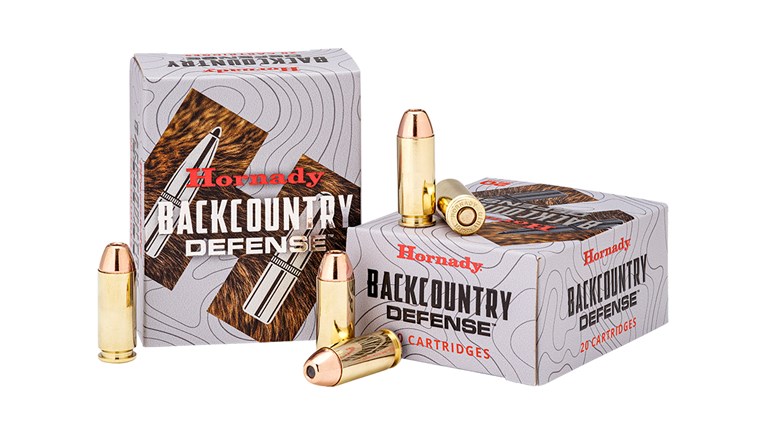

Step 5 - Confirm: You probably have a bullet in mind, but confirm it will provide the external and terminal ballistics you desire. Compare its ballistic coefficient (BC) with your target velocity to predict downrange performance. For personal-defense ammo, confirm the bullet is designed to expand at the impact velocities you expect to see at target distances.

Step 6 - Powder: This is where it can get complicated, but fortunately there’s a multitude of data online for SAAMI (Sporting Arms and Ammunition Manufacturers Institute)-approved cartridges. Select a powder with data for the bullet weight you’ve chosen. Reduce the charge weight by 10 percent, and start there.

For handloading wildcat cartridges, or for bullets for which you cannot find data, pick something close. For example, my 2Fity Hillbilly wildcat cartridge is simply a 6.5 Creedmoor necked to .257. So, Creedmoor data should be close, but since .257-caliber bullets are smaller in diameter, maximum loads will be slightly less for the same bullet weights.

Hodgdon’s Creedmoor data with a 107-grain bullet shows a velocity of 3,076 fps with a maximum charge of 41.5 grains of CFE 223 powder. I reduced that by 10 percent for a starting point, with the assumption 3,000 fps should be obtainable with a 110-grain bullet. You can use the same type of extrapolation for bullet weights for which you have no data when loading SAAMI-approved cartridges.

Step 7 - Load: Charge cases and seat bullets. Weigh every powder charge, loading 10 cartridges in increasing charge-weight increments equaling 1 percent of the starting load. (Use a Sharpie to write the charge weight on each case for reference.) Start with bullets seated .50 off the lands or possibly a bit closer if you know your rifle. Like with the case necks, check bullet run-out and cull cartridges with more than .003-inch deviation.

Step 8 - Shoot: Start with the lowest powder charge and shoot all 10 cartridges at the same target, using the same point-of-aim, and note where each shot lands. (This is where a spotting scope comes in handy.) Take your time, don’t let the barrel get too hot, watch for excessive pressure signs, and record every velocity. If at anytime you exceed the listed—or reasonable velocity—stop; your loads are overpressure. Remember, short barrels will not deliver published velocities because such listings are obtained with 24-inch test barrels.

Step 9 - Evaluate: You’re looking for shot clusters with similar velocities and charge weights. Essentially, you’re trying to find a recipe that induces consistent barrel vibration. If you see no clusters or if velocities are inconsistent, adjust bullet-seating depth, switch primers or powder and start over. You’re also determining if you’ve reached or exceeded your target velocity. If you have, back off to a load that was safe. If you haven’t, you may need to change powders or seat the bullets closer to the lands (decreasing the distance by .001 at a time) to bump pressure.

Step 10 - Corroborate: If you find something you like, load nine or 10 rounds duplicating that recipe, and test with multiple three- or five-shot groups. The goal is corroboration of a velocity and precision consistency that meets your needs. If you’re unsatisfied, work with seating depth, or a different primer or powder. Remember, if you change the recipe in any way, reduce by 10 percent and follow steps one through 10 again.

Is that technical enough of a handloading procedure for you?